Making of A13 part two

Much of the infill work is always trued up flat and square before any of the work commences, as in most woodworking projects.

In this picture are the rear infill sides showing the frog area routered away and this gives me a datum stop which helps me work out the drilling positions and its position in the plane. This will also be the same with the handle.

This is one pair of A13 rear infills being drilled for rivet spacers. Note the frog cut out being used as a stop. After this is done then I can drop a template over the holes to mark out the cutting line for band sawing.

This is the handle being drilled for rivet spacers using the same stops. As you can see I am making planes with rosewood and boxwood at the same time.

Whilst the holding fixture is still in position on the CNC milling machine it is prudent to use this for other work as all the datum positions are set up. Breaking down and setting up can be very time consuming and a little tiring on the grey cells.

This picture shows the finger hole and handle being roughed out.

As I have said; taking advantage of the holding fixtures before they are taken down.

This is the final cut after using the band saw to cut the infills out. I use the CNC mill to cut the true form of the sides. I add on a few thou all round for better finishing.

Using a manual milling machine with a purpose made cutter to produce a moulded form on the front bun. This is very accurate on a milling machine especially equipped with a DRO.

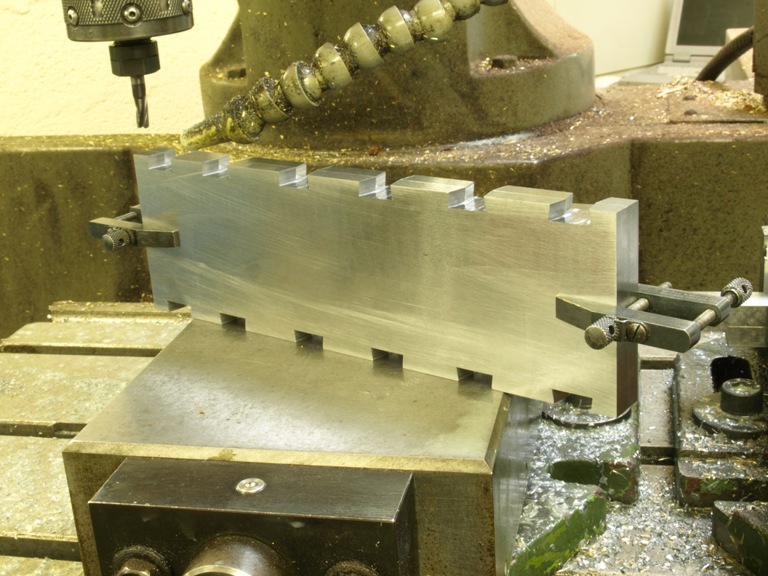

Milling the dovetail pins on the A13 plane bottoms.

Milling these is very advantageous on a CNC milling machine as I can work two bottoms together face to face in mirror form. I have a left and a right side of the bottom being worked together. With a dovetail form cutter and tracking in a butterfly pattern this allows me a left and right cut. I use three different cutters for this process – roughing, finishing and form cutters.

After cutting the compound dovetails in the plane bottoms.

At the risk of criticism from the purists I will say that with some very careful setting up I can produce a near perfect fit between the sides and the bottom without filing.