Conclusion of making the A13 dovetailed infill planes

For a long time I have procrastinated in writing a blog, and in that time I have kept a library of pictures of plane making throughout my range hoping to document it over time.

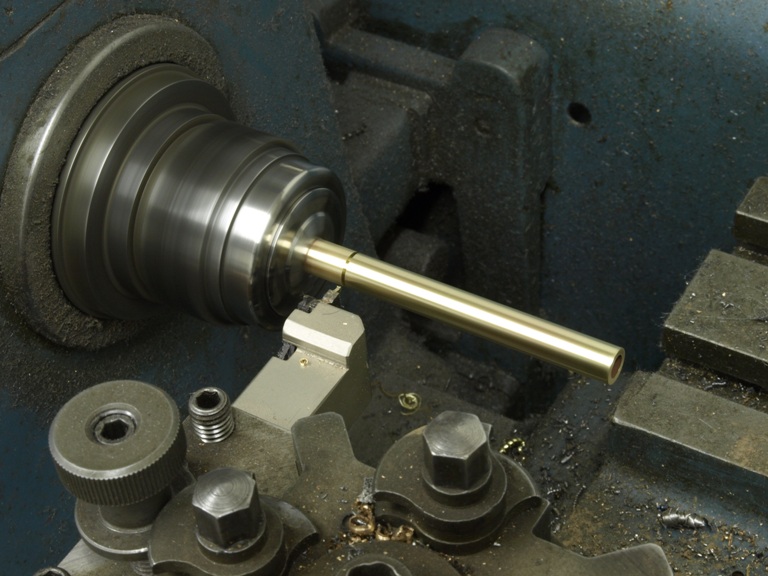

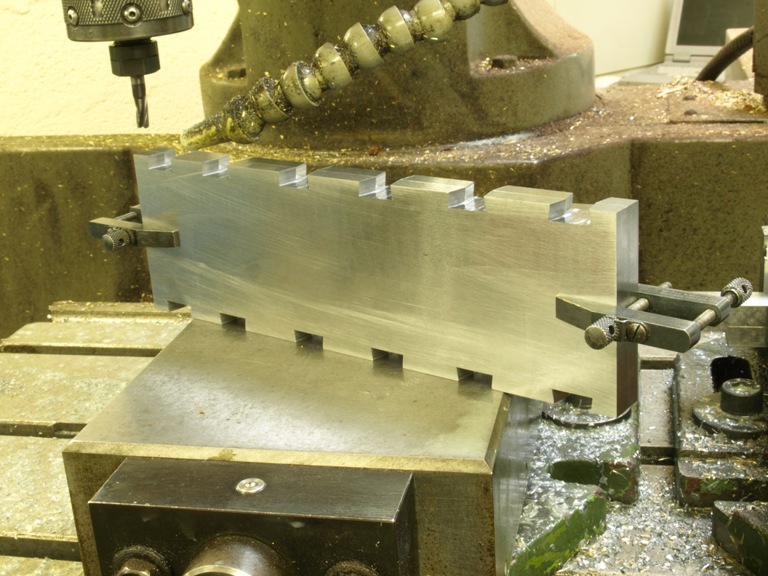

With the A13 I have tried to give some idea of the sheer effort that goes into the making. Although I have missed out much of the story, I hope it is enough to provide an overall picture. I have shown the mixture of hand and machine work that is necessary to achieve something of this quality. Also, I hope that I have shown that the machine work is not an economy but a necessity.

I decided to make the A13 because I could see potential in this design and its very appealing aesthetics, and it has turned out to be my best seller. From the blog you will see that a lot of detail has been upgraded. Some of the enhanced contours have been copied by others and referred to as an A13 when in actual fact it is a Holtey designed A13 and not a Norris. The original Norris A13 was cast iron which supported a square bun. However the introduction of dovetailing (mainly brass on steel) and riveting through metal spacers are all my ideas.

With the completion of these few planes, I feel that I want to move on and look for a replacement for this infill design.